Manufacturing

with Codejig

A reliable approach for long-term perspectives

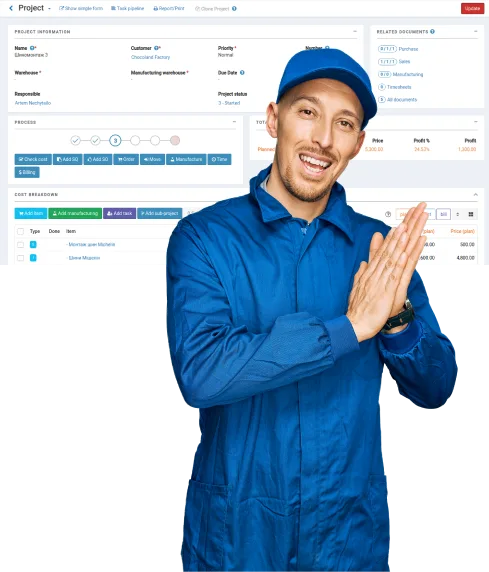

Treat Jobs as Projects

Do you produce goods according to customer orders or have to handle varying manufacturing jobs like repair or manufacturing of custom equipment? Do you have to estimate and track costs for such jobs? Take a look at the project management module of Codejig ERP. It allows for holistic management of manufacturing jobs of various complexity. The project breakdown allows for tracking of labor, raw materials, inventory and sub-contractors.

Read more...

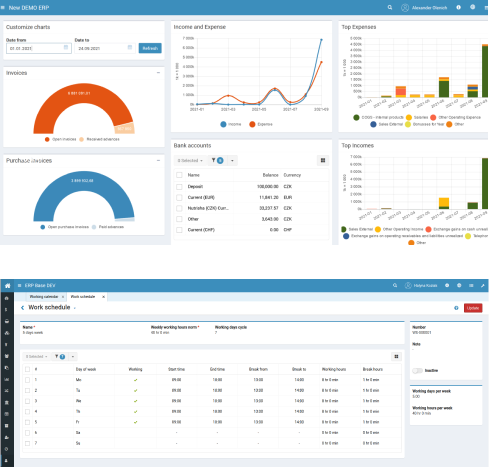

Modular ERP

Particular types of solutions, such as Job costing, Payrolling and Inventory management can be obtained directly from modules of our ERP system. With Codejig ERP, your company gets a powerful and simple business management solution tailored exactly to its needs and business practices. Taking advantage of a full overview of activity in real-time, managers can plan more efficiently, identify areas for improvement, and take action to reduce costs. ERP structure allows use only of the functionality you need and effortless integration with other parts if needed.

Manufacturing Use Cases

Success stories of our customers

Furniture Factory Solution

For a manufacturing business to succeed, it takes more than excellent craftsmanship. Codejig’s factory solution calculates salaries according to the work done by each employee each day, based on assigned tasks. Production picks up the orders based on stages and assigns them to shift workers. After completing an order or production stage, a supervisor marks it once when finished. The system enables employers and employees to calculate daily wages and accrued salaries for each employee. As a result, our client:

- Significantly increased their performance.

- Streamlined supply chain.

- Got furniture and related hardware to distributors and consumers faster.

Air Conditioning Company Solution

Leader air conditioning company deals with a lot of orders with different levels of complexity simultaneously. Among the features of the system is the monitoring of tasks and time spent on them, inventory and warehouse management, purchases, warranties, invoicing, and financial management. Every order is treated as a separate project, and the management can view the estimated costs-margins-sales of every project and for the entire organization. The Codejig solution allows to:

- Operate efficiently and profitably.

- Streamline back-office and field service operations.

- Manage customers, scheduling, dispatching, and invoicing.

Wagon Repair Factory

Codejig software provides automation of the end-to-end lifecycle of the repair process as well as time, labor tracking and inventory management which includes:

- Production management with the repair of each wagon.

- Calculation of estimated costs for wagon repairs (cost of parts and labor) and tracking actual costs of repairs.

- Inventory management (some parts are supplied by customers while others are obtained from the factory).

- Journal management with maintenance records for safety-critical equipment.

- Payroll calculation based both on time and work performance.

- Customer portal which displays all relevant information like a listing of all contracts, invoices, payments, current balances, stock levels of customer supplied inventory and its usage, the listing of wagons and their processing stage, etc.

- Integration with 3rd party accounting software.

Brewery Solution

Finnish brewery has a wide distribution network and specific technology for brewing on the finest beer. Solution with Codejig automated preparation process and progress tracking, which included calculation of the amounts of raw components for various recipes, management of the tanks, tracking of the different parameters, such as temperature, pressure and duration. We also developed a solution for distribution, which allowed tracking every batch and packaging returns, invoicing and taxes management.

- System for the every step of the production — from initial components till packaging returns.

- Automated and comfortable invoicing.

- Smart software for resource management.

Didn’t find solution for your industry?

Leave your contacts and we will get in touch

- Codejig builder overview

- Platform structure

- Use of main features

- User experience tools

- Relevant use cases